Overview

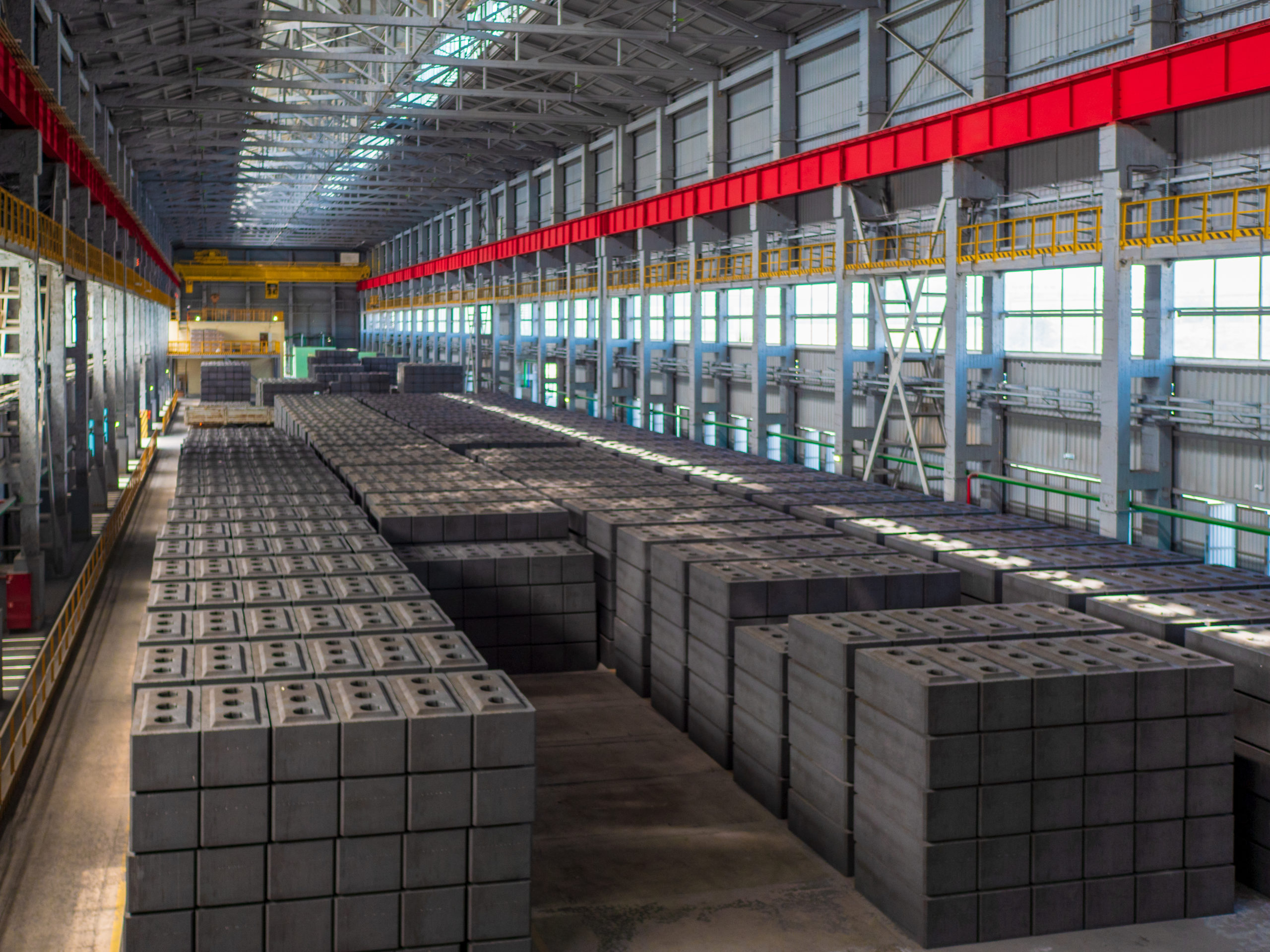

In the aluminum industry, it is important to produce high-quality green anodes to ensure better efficiency of the smelting process. Green Anode Plants (GAP) face many challenges, such as variability in raw materials, process inconsistencies, and dependency on manual operations, which lead to increased rejection rates and a drop in Anode quality. These challenges directly impact the cost of production, the amount of energy consumed, and the quality of downstream processes. Pulse, an Intelligent Digital Twin, improves GAP operations by using real-time data, optimizing workflows, and offering helpful insights. Through predictive modeling and data-driven decision-making, Pulse solves issues to enhance the efficiency of processes and the quality of products in GAP.